Case study of microgrid interface for drilling rig

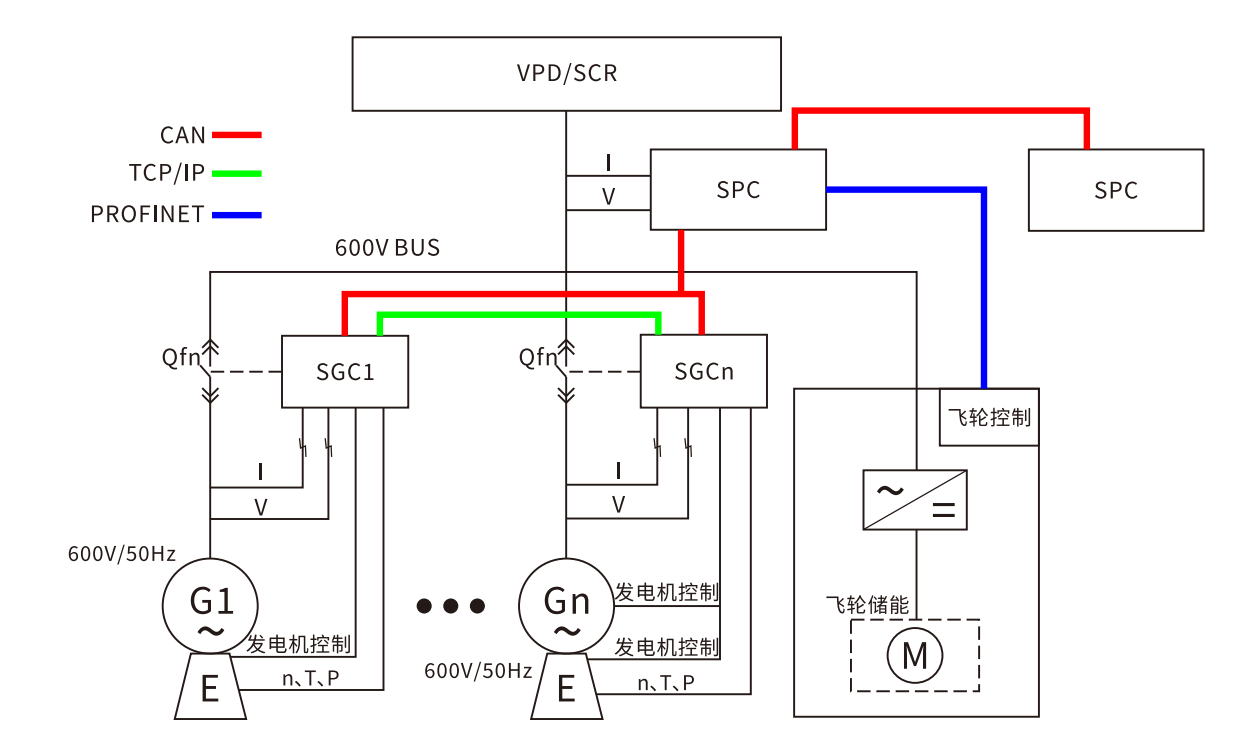

The drilling rig microgrid system includes a diesel power station and a flywheel energy storage system, which are connected through communication for data exchange,Real time processing of data, intelligent control of diesel power plant input and output, intelligent control of energy storage system power output and absorption,The drilling rig microgrid can enable the diesel power station and flywheel system to cooperate reasonably under complex working conditions of the drilling rig, achieving fuel saving, consumption reduction, and intelligenceThe purpose of the work.To make the diesel power station and flywheel energy storage system work better, the interface between the two systems should be clarified.The system developed by Qiming Company for the application of diesel power stations for drilling rigs,Includes single unit controlSGCPower plant controlSPCAccording toFlexible configuration of on-site requirements. multiple unitsSGCCapable of forming islanded power stations, able to collect various parameters of the units and perform operations on themNecessary protection and control, multiple unitsSGCBetween them throughCANandTCP/IPRedundant connection, capable of performing power between the entire power stationRate management and semi-automatic control. Power plant control systemSPCPerform microgrid control, coordination between more isolated power stations, and grid connection of power stations,SPCpassCANThe bus summarizes the data between the entire power station and processes it, configuring it according to the scale and purpose of the power stationSPCBetween systemsThe connection is shown as follows:

After adding the flywheel system, significant fuel savings were achieved during the drilling operation, with a fuel saving effect of over 20%. The number of diesel generators can be reduced. Taking a 7000m drilling rig as an example, a 4x1200kW diesel generator is usually configured. After adding a flywheel system, the unit configuration can be reduced, and a 10x400kW can fully meet the operational requirements.

Application cases of multi energy complementary microgrids for energy storage, photovoltaics, wind power, and generator sets

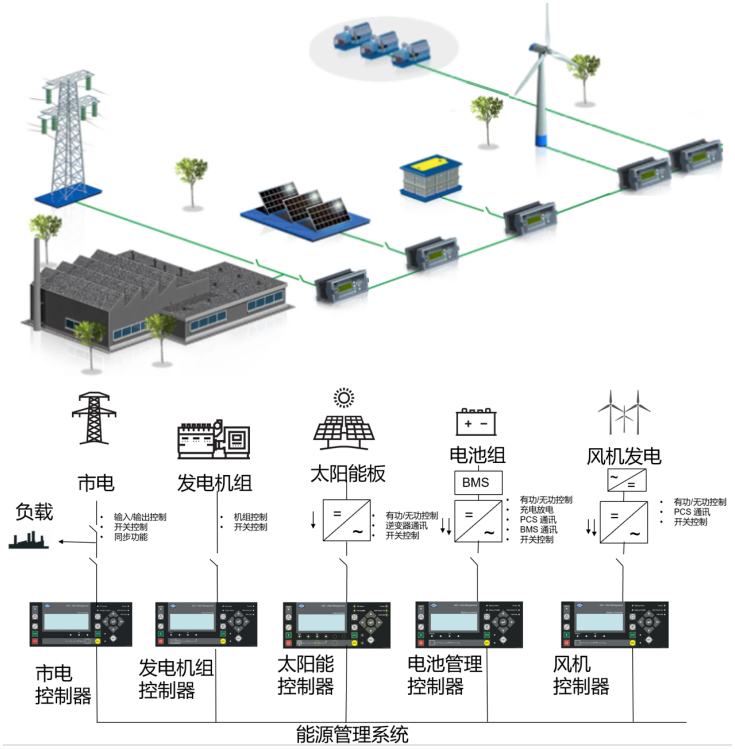

Solutions for docks/industrial parks:

1. Firstly, the mains power prioritizes supplying power to the load.

2. During the day, solar power generation is given priority to supplying power to the dock. When the dock load is low, the solar power source is sufficient and can earn profits from external electricity.

3. When wind resources are abundant, wind power generation prioritizes supplying power to the factory.

4. The main function of energy storage batteries is to peak shaving and valley filling. Simultaneously, it can achieve uninterrupted power supply.

5. When the mains power fails, the energy storage battery is given priority for power supply, and then the power generation unit is restarted. Emergency power supply is provided by the generator set.

6. Thus achieving multi energy complementarity and reliable power supply.

Solution for islanding:

1. Firstly, the generator set generates electricity to provide priority power to the island, and then the generator set is designed as a combined heat and power system to supply hot water to the island.

2. By using wind power generation, solar power generation, energy storage power supply, optimizing the number of operating generator sets for power supply, and reducing the number of operating generator sets to achieve energy-saving effects.